Introduction

There has been a major evolution in the lighting technology applied within automotive applications, moving from traditional incandescent light sources to more advanced types of headlights such as LEDS, OLEDs and adaptive headlamps. While making cars more beautiful, these developments also help in enhancing safety and performance. These lighting systems are used in packed industrial environments and the one of key thing to keep them doing well is proper venting. Venting is crucial to automotive lighting, this article will take a look at why it is important and what problems they solve along with discussing the trends of vent sealing solutions.

The Importance of Venting in Car Lights

Venting provides a two-fold service in automotive lighting - it helps normalize pressure differences within the light housing while managing moisture. These automotive lights face different temperatures hence the air inside them expands or contracts. Pressure Fluctuation: Without a venting system, fluctuating pressure can cause marring of the lens or cabochon due to flex in materials susceptible (polycarbonate is highly flexible) — similar forming during inherent cab-setting and lead lighting methods. Also, moisture from condensation will wear out the effectiveness of the lights and reduce its lifespan. A properly functioning venting system enables the release of pressure and humidity, while at the same time it allows for dust or other contaminant impaction avoided by water.

Venting Systems For Automotive Lighting

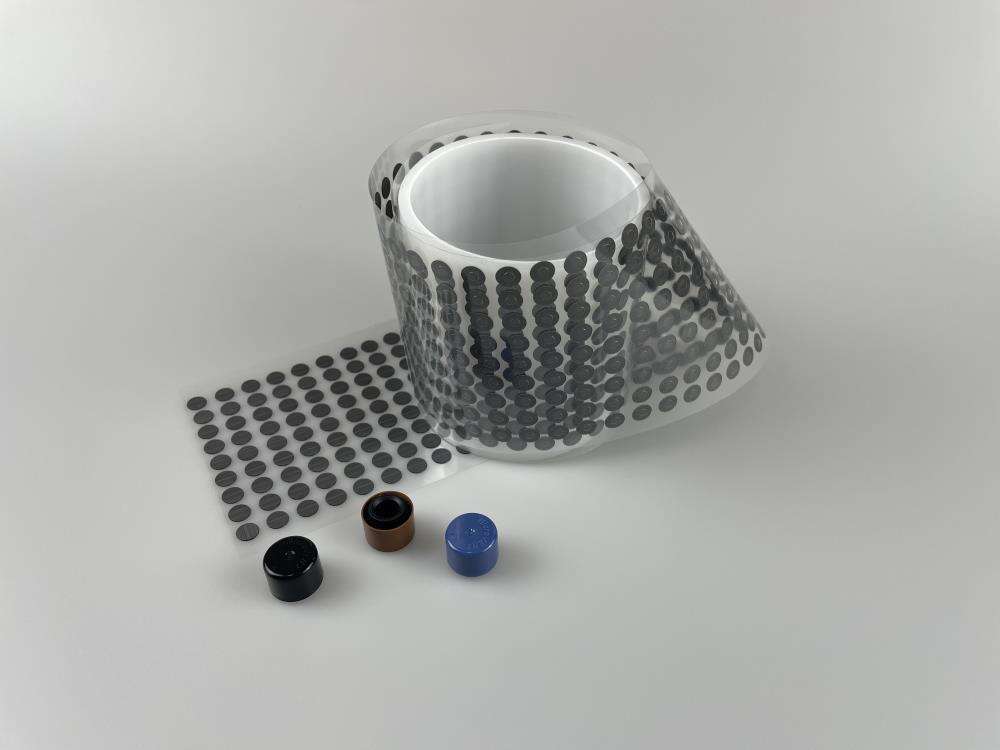

Breather vents are the most popular venting solution found in automotive lighting applications. Small openings or a membrane on these passive vents facilitate airflow in and out of the light housing, to maintain pressure at a steady state or equilibrium. When used alongside breather vents, diffusion vents are designed to enable moisture vapor out while keeping fluids and larger chunks at bay. Combination vents incorporate the two features in a single device, covering both pressure and moisture management.

Materials & Technologies: Automotive lighting vents

The type of material used for automotive lighting vents is very important as it can affect the behaviour and magnetic action of these openings. ePTFE membranes are chosen primarily for their resistance to chemicals and ability to withstand temperature extremes, while still offering exceptional breathability by allowing maximum transfer of moisture vapour outwards. Polytetrafluoroethylene (PTFE) microporous materials, used in Gore™ venting technology deliver a high level of Breathability and are engineered to withstand the challenging conditions auto manufacturers face over time.

The right means of venting — Factors to consider in your design

When designing a venting system, it is necessary to pay attention to the specific requirements of each lighting application. It is a more strategically planned install design considering the location, size and configuration of vents so that it does not impair its effectiveness or look goofy in-transit but still keep lights on & moving air. For example, vents should be in places to allow optimal pressurization and humidity dispersion without becoming at risk from potential pollutants. It is critical that the vents are integrated with sealing systems so as not to compromise the overall integrity of the light fitting.

Automotive Lighting Venting Challenges

Overcoming this challenge means developing a solution that delivers reliable performance in many environments. The vents must be fully operational under extreme temperatures, changing humidity levels and when faced by exposure to water or dust and other environmental factors. One of which is that the vents have to hold up over time, fighting UV radiation and road salt among other factors of aging. The migration toward smaller, more seamlessly integrated automotive lighting systems makes venting them a larger challenge without disrupting the overall system layout.

Automotive lighting vents Test & Safety Standards

Due to the critical nature of these systems, they have a set of performance criteria that must be met through extensive testing. These activities comprise of laboratory tests to determine Breathability, moisture vapor transmission rates (MVTR) and resistance against environmental contaminants. It is also important to conduct field testing of venting systems under different driving conditions, since that too affects how the system works in practice. Meeting industry standards established by SAE International are important in both verifying venting options offer the desired level of protection and performance.

Twosystems specializes in case studies and well-explained examples of successful venting for automotive lighting.

BackgroundA review of various automotive lighting systems highlights the importance that effective venting can have on system performance and reliability. Testing has confirmed that through the use of ePTFE vents in LED headlights, moisture-induced failures can be minimized and provide a longer life for lighting systems. More recently, manufacturers have begun including more sophisticated venting systems in their adaptive headlights helping to keep the bulbs from overheating or condensing under certain weather conditions — which gives these light a higher level of measured reliability with regards to performance and visibility across various weather events.

Automotive lighting venting — future trends

Neither system offers redundancy, as mentioned above, but the next step in automotive lighting venting is most likely a new generation of vent systems that are lighter & more modular. By including sensors and microcontrollers, vents could even modify their behaviour on the fly depending directly on internal conditions of the lighting system. Better venting materials that can take the heat and exposure to automotive wear will also show their stuff due in part to improvements in material science. New kinds of lighting, such as OLEDs and laser-based systems are coming to market in the next few years, which is going to make venting a very big deal.

Conclusion

In closing, venting is the unsung hero of automotive lighting — it underpins light reliability, performance and lifetimes. Vents are included to assist in the closer regulation of pressure and humidity, making these excellent for maintaining light conditions as well as preventing damage from environmental pressures. The automotive industry will continue adopting new lighting technologies and in doing so, the need for efficient venting solutions is only going to increase; this presents itself as a key area of focus on both ends – design teams and engineering folks.

Table of Contents

- Introduction

- The Importance of Venting in Car Lights

- Venting Systems For Automotive Lighting

- Materials & Technologies: Automotive lighting vents

- The right means of venting — Factors to consider in your design

- Automotive Lighting Venting Challenges

- Automotive lighting vents Test & Safety Standards

- Automotive lighting venting — future trends

- Conclusion

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS