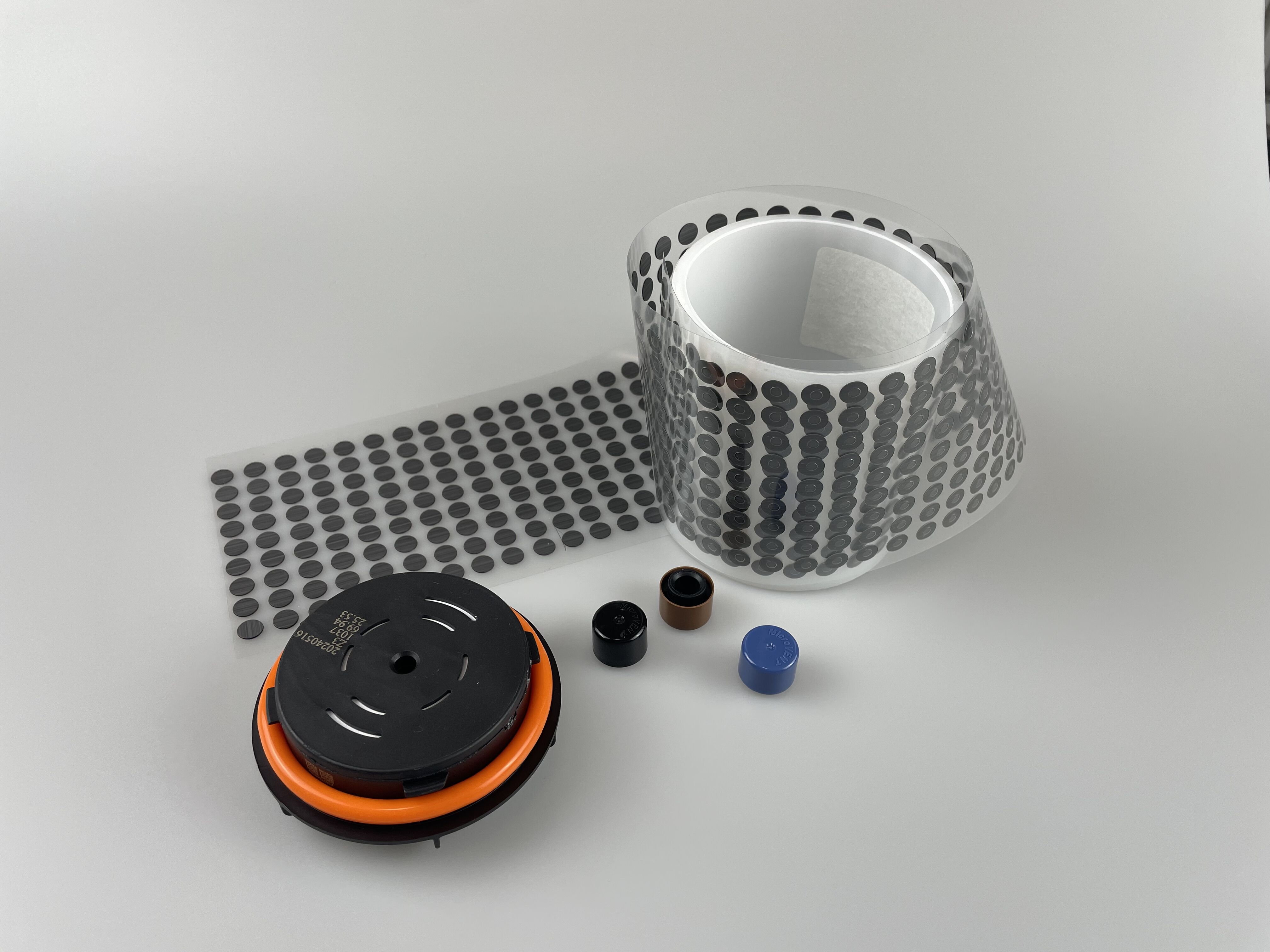

Packaging sensitive Products requires precision to maintain their quality. The Microvent breathing cap plays a crucial role in this process. It regulates airflow, balances pressure, and manages moisture levels inside containers. These functions protect your products from damage caused by pressure changes, leaks, or excess humidity. By using this innovative solution, you ensure the safety and integrity of your goods throughout storage and transportation. This simple yet effective tool helps preserve the longevity of items that demand careful handling.

The Primary Function of Microvent Breathing Caps

Pressure Equalization

Pressure changes inside a packaging container can harm your products. When temperatures fluctuate or altitudes shift, the air inside the container expands or contracts. This creates pressure imbalances that may lead to leaks, bulging, or even container failure. The Microvent breathing cap solves this issue by allowing air to flow in and out as needed. It equalizes the pressure, ensuring the container remains intact and your products stay safe. This feature is especially useful during transportation, where environmental conditions often vary.

Moisture Control

Excess moisture can ruin sensitive products. It promotes mold growth, causes corrosion, and damages packaging materials. The Microvent breathing cap helps you manage moisture levels effectively. Its design prevents water from entering the container while allowing air to circulate. This keeps the contents dry and protected. By controlling humidity, you can preserve the quality of your goods and reduce the risk of spoilage or degradation.

Ventilation for Gas Exchange

Certain products release gases during storage or transport. Without proper ventilation, these gases can build up and compromise the container's integrity. The Microvent breathing cap facilitates gas exchange by allowing gases to escape while preventing contaminants from entering. This function is vital for items like food, chemicals, and pharmaceuticals that require a controlled environment. With this cap, you can maintain optimal conditions for your products, ensuring their safety and longevity.

Key Benefits of Using Microvent Breathing Caps

Product Protection

The Microvent breathing cap ensures your products remain safe from environmental threats. It prevents external contaminants like dust, dirt, and moisture from entering the container. This protection is crucial for sensitive items such as food, pharmaceuticals, and electronics. By maintaining a controlled environment, the cap shields your goods from damage caused by external factors. You can trust it to preserve the integrity of your products during storage and transportation.

Extended Shelf Life

Preserving the quality of your products for a longer time becomes easier with the Microvent breathing cap. It regulates airflow and controls humidity levels, which are essential for extending shelf life. For perishable goods, this feature helps slow down spoilage and degradation. By maintaining optimal conditions, the cap ensures your products stay fresh and usable for an extended period. This benefit not only reduces waste but also enhances customer satisfaction.

Prevention of Container Damage

Pressure changes can compromise the structure of your packaging containers. The Microvent breathing cap prevents this by equalizing pressure inside the container. It allows air to flow in and out, avoiding issues like bulging, collapsing, or leaks. This feature is particularly valuable during transportation, where containers face varying environmental conditions. By using this cap, you protect both the container and its contents, ensuring safe delivery to the end user.

How Microvent Breathing Caps Work

Materials and Technology

The Microvent breathing cap relies on advanced materials and innovative technology to deliver its functionality. Manufacturers use specialized membranes that allow air and gases to pass through while blocking liquids and contaminants. These membranes often consist of polytetrafluoroethylene (PTFE), a durable and breathable material. PTFE resists water and chemicals, ensuring the cap performs effectively in various conditions.

The cap's design incorporates a secure structure that fits tightly onto packaging containers. This ensures no gaps or leaks compromise the container's integrity. The materials used are lightweight yet robust, making the cap suitable for long-term use. By combining these features, the Microvent breathing cap provides reliable performance across different industries.

Mechanisms of Action

The Microvent breathing cap operates through a simple yet effective mechanism. It uses its breathable membrane to regulate airflow and maintain pressure balance. When pressure builds up inside the container, the cap allows air or gases to escape. This prevents issues like bulging or ruptures. Similarly, when external pressure drops, the cap permits air to enter, equalizing the internal and external pressure.

The cap also acts as a barrier against moisture and contaminants. Its membrane blocks water droplets and particles from entering the container. This keeps the contents dry and free from external pollutants. The cap's ability to facilitate gas exchange ensures optimal conditions for products that release gases during storage or transport. This mechanism protects both the container and its contents, ensuring safety and quality.

Common Applications and Industries

Food and Beverage Industry

You often encounter products in the food and beverage industry that require careful packaging to maintain freshness. The Microvent breathing cap plays a vital role here. It helps regulate airflow and controls moisture levels, ensuring that perishable goods stay fresh for longer periods. For example, baked goods, dairy products, and beverages benefit from this technology by avoiding spoilage caused by excess humidity or pressure changes. The cap also prevents contamination, keeping your food products safe and ready for consumption.

In addition, the cap supports the packaging of carbonated beverages. It allows gases to escape without compromising the container's integrity, maintaining the quality of the drink. By using Microvent breathing caps, you can ensure that your food and beverage products reach consumers in optimal condition.

Pharmaceutical and Medical Industry

The pharmaceutical and medical industry demands precision and safety in packaging. Microvent breathing caps meet these requirements by providing controlled environments for sensitive products. Medications, vaccines, and medical devices often need protection from moisture and pressure fluctuations. The cap ensures that these items remain stable and effective during storage and transportation.

For pharmaceuticals that release gases, such as certain chemical compounds, the cap facilitates proper ventilation. This prevents the buildup of harmful gases inside the container. You can rely on this technology to maintain the sterility and integrity of medical products, ensuring they perform as intended when used by patients.

Electronics and Technology

Electronics and technology products are highly sensitive to environmental factors like moisture and pressure. The Microvent breathing cap offers a solution to protect these items from damage. It prevents water vapor and dust from entering the packaging, safeguarding delicate components such as circuit boards, sensors, and batteries.

During transportation, electronic devices often face varying altitudes and temperatures. The cap equalizes pressure inside the packaging, preventing issues like warping or cracking. By using this innovative tool, you can ensure that your electronic products remain functional and reliable when they reach their destination.

Agricultural and Chemical Packaging

In agricultural and chemical packaging, maintaining product stability and safety is crucial. You often deal with substances that are sensitive to environmental changes or potentially hazardous. The Microvent breathing cap provides an effective solution to these challenges by ensuring proper ventilation and protection.

For agricultural products like seeds, grains, or fertilizers, moisture control is essential. Excess humidity can lead to mold growth or spoilage, reducing the quality of your goods. The Microvent breathing cap prevents water from entering the container while allowing air to circulate. This keeps your products dry and preserves their usability.

Chemical packaging requires even greater precision. Many chemicals release gases during storage, which can build up and create pressure inside the container. Without proper ventilation, this pressure may compromise the container's integrity or pose safety risks. The Microvent breathing cap allows these gases to escape safely, preventing accidents and maintaining a stable environment for the chemicals.

You also benefit from the cap's ability to block contaminants. Dust, dirt, and other particles cannot enter the container, ensuring the purity of your products. This feature is particularly valuable for volatile substances that require a controlled environment to remain effective.

By using Microvent breathing caps in agricultural and chemical packaging, you enhance the safety, quality, and longevity of your products. This innovative tool helps you meet industry standards and ensures reliable performance throughout storage and transportation.

Microvent breathing caps provide essential solutions for modern packaging needs. They help you protect products by regulating pressure, controlling moisture, and ensuring proper ventilation. These features make them a reliable choice for maintaining product quality and safety. By using these caps, you can extend shelf life, reduce waste, and improve packaging efficiency. Their versatility across industries like food, pharmaceuticals, and electronics highlights their importance. Incorporating Microvent breathing caps into your packaging strategy ensures safe storage and transport, boosting customer satisfaction and trust in your products.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS