Microvent®️ breathable packaging induction seals serve a dual purpose. They provide a secure seal while allowing controlled gas exchange. This innovative feature helps maintain product integrity by regulating internal pressure. It also ensures freshness and safety by preventing contamination. These seals have become essential in modern packaging, addressing the growing demand for efficient and reliable solutions.

Key Functions of Microvent®️ Breathable Packaging

Regulating Air Pressure and Preventing Leakage

Microvent®️ breathable packaging plays a critical role in managing air pressure within sealed containers. Changes in altitude or temperature can cause pressure imbalances, leading to potential leaks or damage to the packaging. The breathable membrane integrated into these seals allows controlled gas exchange, equalizing internal and external pressure. This feature prevents the packaging from bulging or collapsing, ensuring the product remains intact during transportation and storage. By maintaining a secure seal, it also minimizes the risk of spillage, enhancing the reliability of the packaging.

Maintaining Freshness and Product Quality

Preserving product freshness is a key priority for many industries. Microvent®️ breathable packaging achieves this by allowing gases like oxygen and carbon dioxide to pass through the membrane selectively. This controlled exchange helps maintain the ideal environment for perishable goods, such as food and beverages. For instance, fresh produce often releases gases that can build up inside sealed containers. The breathable seal prevents this accumulation, reducing spoilage and extending the product's shelf life. As a result, consumers receive Products that retain their original quality and flavor.

Protecting Against Contamination

Contamination poses a significant threat to product safety. Microvent®️ breathable packaging incorporates advanced membrane technology that acts as a barrier against external contaminants, such as dust, moisture, and microorganisms. While allowing gases to pass through, the membrane blocks harmful particles from entering the container. This dual functionality ensures that the product remains safe for consumption or use. Industries like pharmaceuticals and healthcare benefit greatly from this feature, as it helps maintain the sterility and integrity of sensitive products.

How Microvent®️ Breathable Packaging Induction Seals Work

The Science of Breathable Membrane Technology

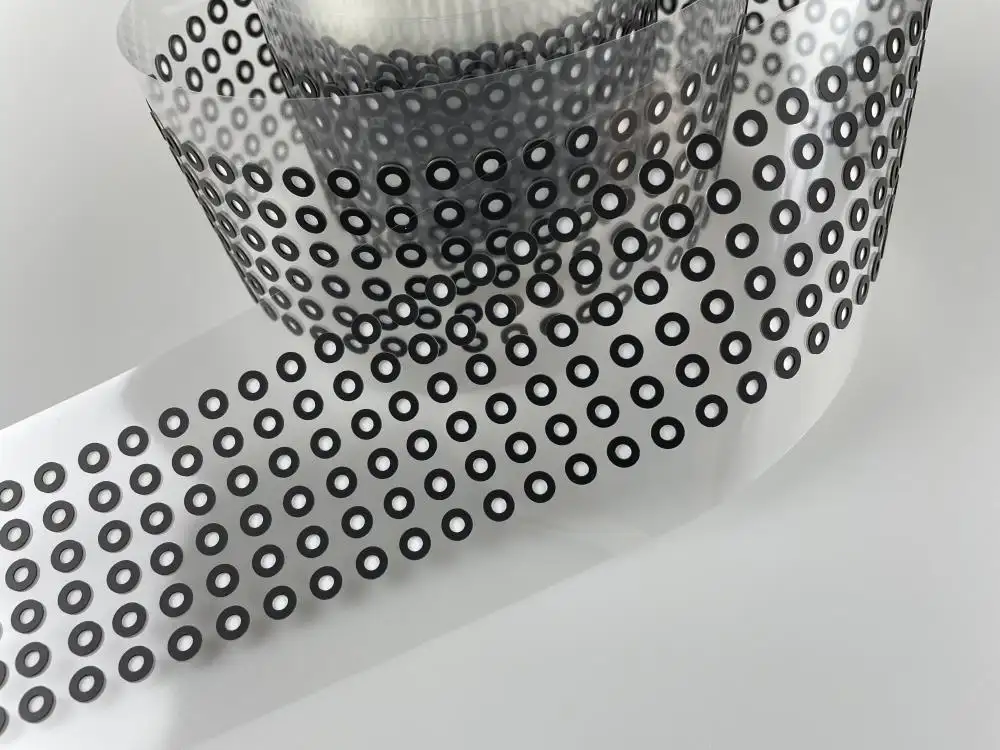

Breathable membrane technology relies on advanced materials that allow selective gas exchange. These membranes contain microscopic pores designed to permit gases like oxygen and carbon dioxide to pass through while blocking liquids and solid particles. The pore size and material composition determine the membrane's permeability. This technology ensures that products remain protected from external contaminants while maintaining an optimal internal environment. Industries requiring precise atmospheric control, such as food and pharmaceuticals, benefit significantly from this innovation.

The Induction Sealing Process Explained

Induction sealing uses electromagnetic energy to bond the Microvent®️ breathable packaging seal to the container. The process begins with placing the seal on the container's opening. An induction coil generates heat through electromagnetic induction, activating the adhesive layer on the seal. This creates a secure bond between the seal and the container. The process is non-Contact, ensuring hygiene and efficiency. The breathable membrane remains intact during sealing, preserving its functionality.

Combining Airtight and Breathable Features

Microvent®️ breathable packaging induction seals achieve a balance between airtightness and breathability. The outer layer forms a robust barrier, preventing leaks and tampering. Simultaneously, the breathable membrane allows controlled gas exchange, maintaining product quality. This dual functionality makes these seals ideal for products requiring both protection and ventilation. By combining these features, manufacturers can ensure product safety without compromising freshness or integrity.

Benefits of Microvent®️ Breathable Packaging

Extending Shelf Life and Reducing Waste

Microvent®️ breathable packaging significantly extends the shelf life of products by creating an optimal storage environment. The breathable membrane regulates gas exchange, preventing the buildup of harmful gases that can accelerate spoilage. This feature is especially beneficial for perishable goods like fresh produce, dairy, and baked items. By maintaining product quality for longer periods, manufacturers can reduce waste caused by premature spoilage. Retailers and consumers also benefit from fewer discarded products, contributing to more sustainable practices across the supply chain.

Enhancing Tamper Evidence and Consumer Safety

Tamper evidence is a critical aspect of modern packaging. Microvent®️ breathable packaging induction seals provide a secure barrier that clearly indicates any unauthorized access. The induction sealing process creates a strong bond that cannot be resealed once broken, ensuring product integrity. This feature enhances consumer trust by guaranteeing that the product remains untouched until it reaches the end user. Additionally, the breathable membrane prevents contamination from external particles, further safeguarding consumer health. Industries like pharmaceuticals and food production rely on this technology to meet stringent safety standards.

Improving Packaging Efficiency and Cost-Effectiveness

Microvent®️ breathable packaging improves efficiency by streamlining the sealing process. The induction sealing method is fast, hygienic, and reliable, reducing production downtime. Manufacturers benefit from fewer packaging failures, which lowers costs associated with damaged goods or returns. The dual functionality of airtight sealing and breathability eliminates the need for additional packaging components, further reducing material costs. This innovation allows businesses to achieve high-quality packaging solutions while optimizing operational expenses.

Microvent®️ breathable packaging induction seals deliver a unique combination of secure sealing and controlled gas exchange. Their functionality ensures product safety, freshness, and extended shelf life. These seals enhance packaging efficiency while reducing waste. Businesses across industries can benefit from adopting this innovative solution to meet modern packaging demands and improve customer satisfaction.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS