Introduction

When considering the outdoor elements, protection is key in portable electronics and outdoors gear. From the great outdoors to bumpy office commutes, it helps having gear that is water-resistant and dustproof which be a boon when temperatures are boiling or well below freezing. Introduce ePTFE (expanded polytetrafluoroethylene) membrane, a technology which changed the way we secure our gadgets. In this article, we look into the general overview or structure of ePTFE and its properties, where it is used for equipment protection and how polished absorbers made out of expanded PTFE also contribute positively towards audio quality while providing a buffer to environmental effects.

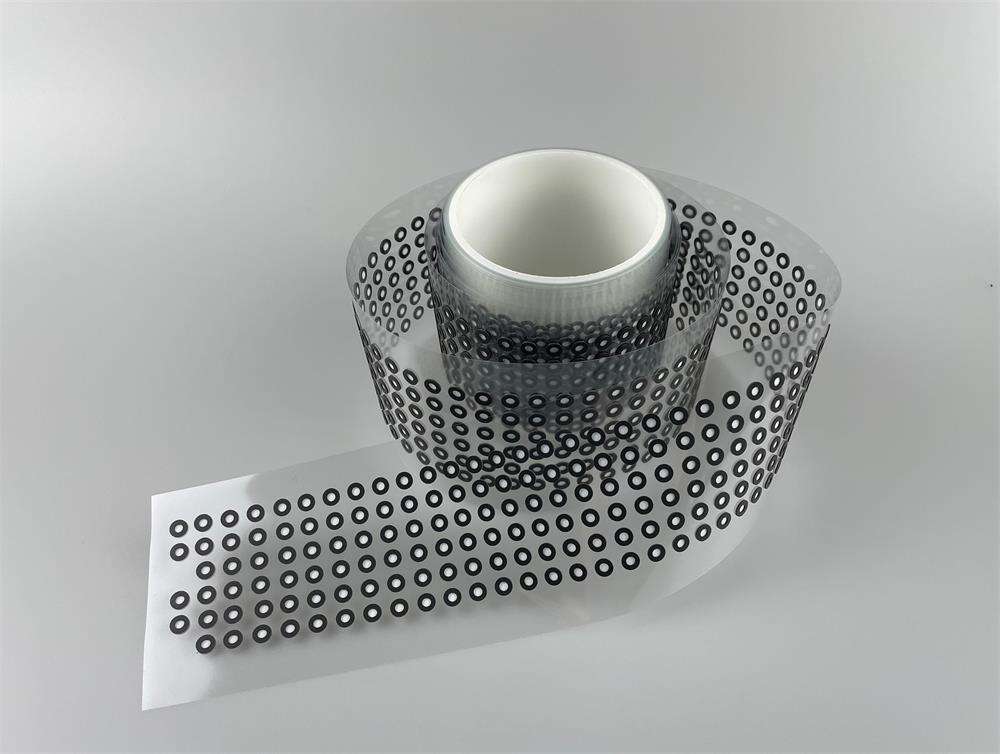

ePTFE membrane type and properties

ePTFE membrane is a one-of-a-kind material that features distinct microscopic pores in its microstructure composed of flexible nodes and fibrils. These pores are high-precision in size, permitting the membrane to be permeable while likewise giving an imperviousness to contaminants. It shows acid, alkalis and solvents resistanceproperty in this application form thanks to the exceptional chemical resistance of ePTFE. ePTFE — a material type that often has chemical resistant additives to help further extend the life of the product, making it an excellent choice for when you need reliability from wear due to harsh environments.

Applications of ePTFE for protecting equipment

The usage of ePTFE membrane in equipment protection is wide. In the realm of wearable tech, ePTFE coats sensors in smartwatches and fitness trackers to keep them breathable yet safe from sweat or water. For example, ePTFE automatically seals out dust and moisture for outdoor electronics including telecoms devices, which must function without fault in the most exposed of environments.

AccentureAlthough heat-resistant ePTFE aramids are used in protecting Body MRI from sensitive equipment. Its properties make it very useful in the fabrication of sterile barriers which are used to prevent contamination while allowing essential air flow requirements for medical sensor/anti-scalable system i.e isobaric pressure sensors and monitors.

Protection to the Environment ePTFE Membrane

Energy efficient ePTFE membrane also provides very unique value regarding its environmental protection function. It does not allow dust and particulate matter that are useful in case of equipment used under hard environs. Furthermore, as ePTFE is a hydrophobic, it has fantastic resistance to water which makes it suitable for when you need protection against moisture.

Another critical trait of the material is its ability to resist temperature extremes, which insulate your equipment from both heat and cold escalating. This ensures that no matter the climate or conditions under which they are operating, equipment function is preserved.

Improving the Sound of Audio with an ePTFE Diaphragm

In addition to safeguarding sensitive equipment, the ePTFE membrane boosts sound quality. Sound transparency: prevents sound from being muffled, meaningit can be used within speakers and microphones without significant loss of fidelity. In addition, the noise reducing effect of ePTFE is that a considerable amount of sound would be absorbed at different frequencies and environments to deliver pristine acoustics in many professional scenarios.

ePTFE Membranes Maintenance and Cleaning

Cleaning ePTFE surfaces is simple as the material's non-stick surface and fouling-resistant properties require minimal maintenance. Moreover, the photo-catalytic degradation of organics incorporated visible light exposure results in self-maintaining membrane which can kill bacteria as well and keep working over time.

Challenges and Solutions Of ePTFE Membrane Integration

The addition of ePTFE membrane to your product can be a tricky thing, as achieving the right combination for breath ability and protection is no simple task. But, again, these limits can be worked around by utilizing a variety of advanced materials and design innovations. The future of ePTFE developmentEfforts geared towards refining the technology in order to ensure long-term reliability and durability are also underway, with ongoing research into 21 st century PTFE increasingly focusing on developing materials that can be adapted for smart tech.

14 Future of ePTFE Membrane Technology

ePTFE Membranes is a bio-inspired material and it has strong features against harsh environments. The future development of ePTFER membrans technology will focus on bionic (biform Vent), intelligent membrane technology. An interesting area for further investigation is the integration with IoT and smart sensors to monitor protection in real-time. What is more, efforts for sustainability are also leading to production of ePTFE membranes by greener means.

Conclusion

The multifunctional nature of the ePTFE membranes significantly contribute to equipment protection through improved robustness and performance while ensuring audio transparency. To put it short, progress in ePTFE technology will enable more advanced use of the material with equipment design that offers improved protection and less intrusive Products as well. This is why we are confident that ePTFE membranes will continue to be a vital part of the fabric for high performance equipment reliability well into the future.

Table of Contents

- Introduction

- ePTFE membrane type and properties

- Applications of ePTFE for protecting equipment

- Protection to the Environment ePTFE Membrane

- Improving the Sound of Audio with an ePTFE Diaphragm

- ePTFE Membranes Maintenance and Cleaning

- Challenges and Solutions Of ePTFE Membrane Integration

- 14 Future of ePTFE Membrane Technology

- Conclusion

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS