While to consumers packing affects attractiveness, to consumer goods packing not only improves market image of a product but ensures safety and workmanship inside it. An important, yet often overlooked element of bottle packaging is the vent polyethylene (PE) liner; a small but crucial feature that plays an out sized role in protecting and preserving the product for sale.

Understanding PE Liners

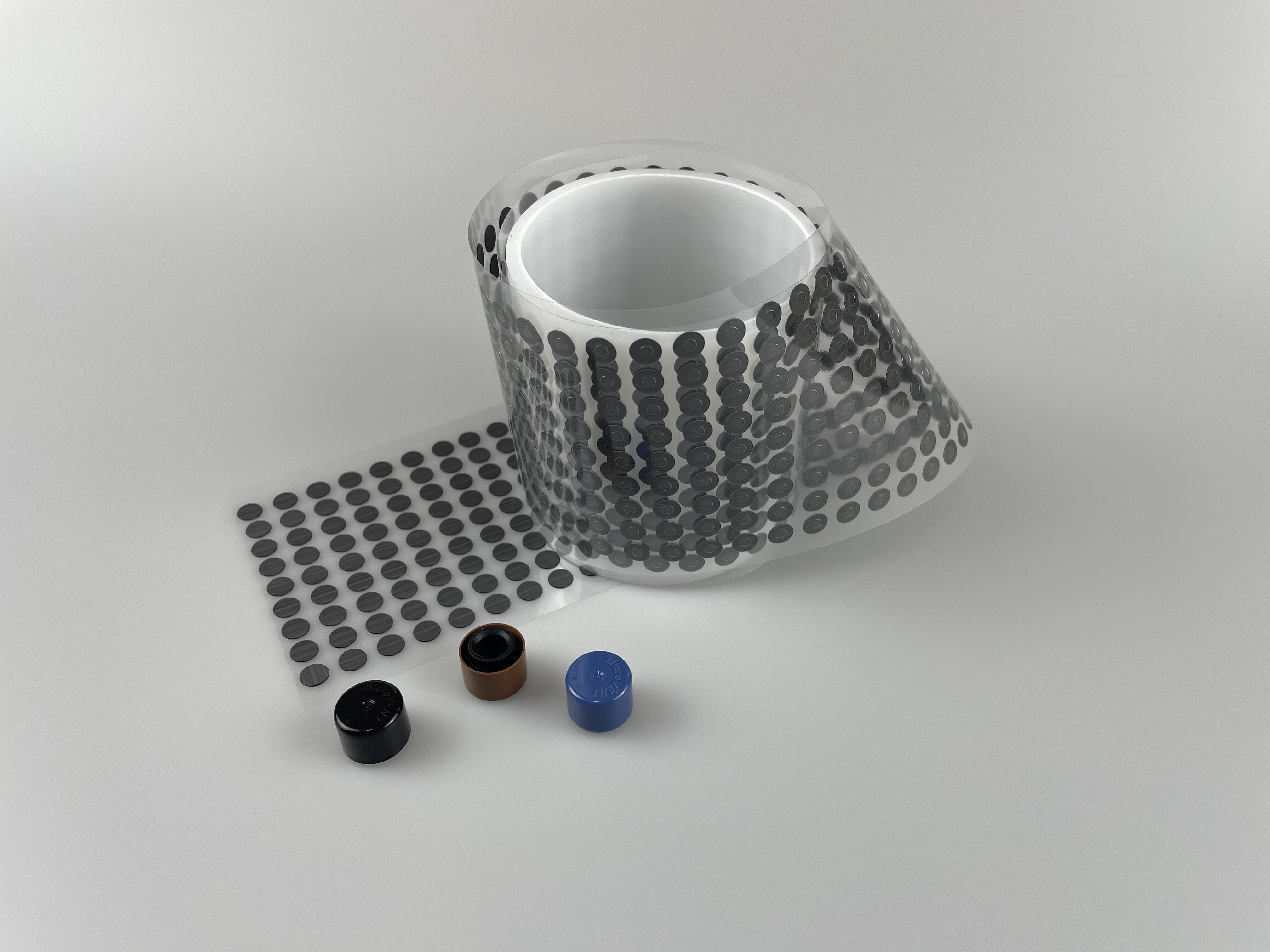

PE liners are polyethylene layer that seals in a bottle cap. They act as a gateway between the Products and outside, sealing off the leaks and contamination. In particular Vent PE liners are equipped with tiny channels or holes, which allow balancing the pressure inside of a bottle — and this is crucial to keep the product high-quality and the package undamaged.

Application of Vent PE Liners

A vent PE liner is designed to balance the atmospheric pressure within a bottle. When a product is filled in a container, the pressure inside the bottle is pressurized or reduced depending on ambient temperature or altitude. The bottled water will bulge and leak or even explode if without a vent due to this expansion. Aeration is made with ventilated PE liners which permit the exchange of air, corresponding atmospheric pressure inside and outside packaging that preserves natural shape against any possible deformation or potential rupture.

Three Key Benefits of Vent PE Liners

The most important technical benefits of vent PE liners are the prevention of pressure accumulation and vacuum formation. This is especially critical for products that are sensitive to changes in internal pressure, such as carbonated drinks or those in flexible packaging. The vent PE liners allows for the controlled pressure release, this keeps the bottle structure and prevents any product leakage or seepage.

In addition to these, vent PE liners aid in improving shelf life of a product. These liners maintain the quality of product within by regulating the internal environment of the bottle thus preventing spoilage from pressure-associated factors. Its helpful especially for perishables and product with shelf life.

Vent PE Liners Safety Features

Various safety features make vent PE liners an essential packaging need as safety always rules first. They prevent the possibility of contamination, allowing the product in that bottle to be safe for consumption. Also, PE materials are very high-quality and good for the product as they have great resistance to chemicals and corrode which makes it a perfect fit even in aggressive chemical compositions.

Another key consideration in vent PE liners is that of compliance with the safety and hygiene standards. They comply with strict industry standards, allowing the user to be secure about the product as well as its packaging.

In the case of Vent PE Liners

Vent PE liners are used in multiple industries including food & beverages, pharmaceutical and chemical. They are, therefore, utilized in the food industry to pack items such as sauces, drinks, and condiments. In the pharmaceutical sector they guard against environmental factors that may otherwise affect the efficacy of medications. In the chemical industry, they are responsible for safely holding dangerous materials.

Vent PE Liner Technology Improves upon Existing Vent PE Liner Innovations

Vent PE liner technology is developing. Recent advancements in materials and manufacturing processes have resulted in the creation of liners that are better than before in terms of sealing capabilities, and are more effective against environmental exposure. How future packaging will be smart: It might come integrated with smart packaging solutions like an indicator that changes color when the seal is breached.

Recent innovations were influenced by sustainability and environmental consideration. Manufacturers are looking at biodegradable materials and recycling processes to reduce the ecological footprint of PE liners.

Challenges and Solutions

As useful as they are, vent PE liners can also become problematic problems regarding compatibility with various bottle types and even having difficulty sealing tightly enough. Manufacturers will then react to these issues by testing and producing specialty adhesives and sealants to create a good bond the liner has with the bottle.

Another issue conflicts with the requirement for uniformity of quality and performance. This is dealt with via QC and industry standard procedures to make sure every liner meets specs for function as well as safety.

Future Trends

In terms of vent PE liners, ongoing liner technology innovations will likely determine its future in the goals of safer and sustainable swine production. More brands will differentiate by crazy new packaging features, but you also again have that customization and personalization — these won't be a one-size-fits-all approach any more. Changes to liner design and application will also result from regulatory changes as new safety and environmental standards are require.

Conclusion

Lastly, vent PE liners are a vital component for protecting bottle packaging by balancing internal pressure within the container to control leakage from inducing over pressurization in the bottle when temperature fluctuations occur helping ensure the safety and quality of your packaged product. With continued advances in technology and industry focus on safe and sustainable production, vent PE liners will play an increasingly central role in packaging. Both product protection and consumer safety will benefit from on-going innovation in this small but crucial component of packaging.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS