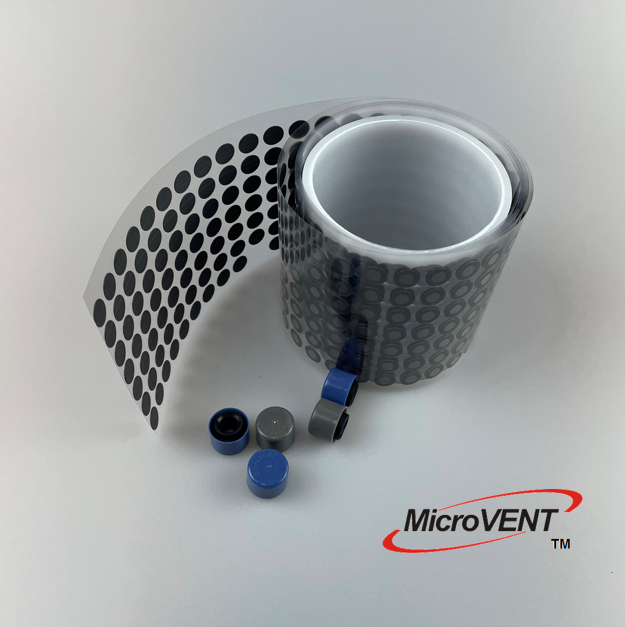

air vent plug

An air vent plug is a specialized mechanical device designed to control airflow within various systems and installations. This innovative component serves as a critical element in maintaining optimal pressure balance, preventing contamination, and ensuring efficient operation across diverse applications. The air vent plug functions as a controllable barrier that can either permit or restrict air passage through ventilation systems, ducts, or enclosed spaces. Its primary purpose involves regulating atmospheric pressure differences while maintaining system integrity and performance standards. The device typically features a robust construction that withstands environmental challenges and operational demands. Modern air vent plug designs incorporate advanced materials that resist corrosion, temperature fluctuations, and mechanical stress. The plug mechanism operates through various activation methods, including manual adjustment, automatic response to pressure changes, or remote control systems. Key technological features include precision-engineered sealing components that ensure airtight closure when activated. The internal mechanism often utilizes spring-loaded or valve-based systems that respond to predetermined pressure thresholds. Many contemporary models incorporate smart sensors that monitor environmental conditions and adjust the plug position accordingly. The air vent plug construction typically involves durable materials such as stainless steel, high-grade plastics, or specialized alloys that maintain structural integrity under challenging conditions. Surface treatments and coatings enhance longevity and performance in corrosive environments. Installation flexibility represents another significant feature, with standardized mounting configurations that accommodate various system requirements. The device integrates seamlessly with existing infrastructure while providing reliable long-term operation. Applications span numerous industries including HVAC systems, industrial processing facilities, marine installations, and automotive applications. The air vent plug proves essential in maintaining system efficiency, preventing pressure-related damage, and ensuring optimal operational conditions across these diverse environments.